Biocircuits for Evolutionary Biotech

Synthetic bio sensor circuits for evolved pharmaceutical biomanufacturing

Problems & Goals

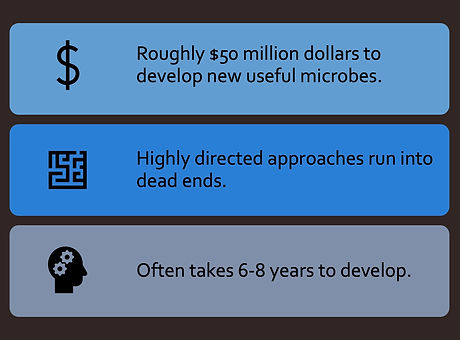

Developing new useful microorganisms for renewable chemical production, bioremediation, agricultural and of course medical applications is extremely time and capital intensive, typically taking 50 million USD and eight years to complete. We modified an existing synthetic biosensor to measure the pharmaceutical dopamine, a trauma treatment, in conjunction we used a circuit simulator Cadence to predict improvements to the biosensor, which ultimately is designed to be used for high throughput evolution. Evolution with the associated benefits of reducing hypothesis testing and directed engineering will allow hundreds to thousands times faster screening than existing machines, thus reducing timelines and costs.

Biosensor

To screen cells we genetically modified a plasmid-based biosensor to generate a fluorescent signal in response to dopamine production in the cells. The resulting sensor was sensitive to dopamine from the expected starting concentration of the cells to the projected commercially viable concentration. With this easy to use sensor, we hypothesize the best molecule producing cells among a randomly assorted population of millions can be screened every day by their fluorescence to evolve them to be industrially viable.

Sensor Optimization

In simulation we varied the copy number of the plasmid and a promoter strength to find improved version of the biosensor in terms of energy usage, log-linearity of the input output dynamics, and the on-off ratio. This allowed us to find an optimized biosensor that would improve future evolutionary studies.

Production and Evolutionary Next Steps

To establish cells that can produce dopamine at the dopamine sensor’s low end of sensitivity we worked to replicate the work of previous researchers. Using their design we successfully constructed the dopamine production plasmid, however due to the pandemic the precursor overproduce plasmid was not completed. Once finished we would randomly mutate the organisms and screen them using the biosensor. Applied iteratively, generating diversity and selecting the best producers would evolve cells to be ever more productive, and eventually reach the yield, titer, and rate requirements for industrial production.